Material Decarbonization by FLD Technologies

Opening new dimensions of the hydrogen circular economy and decarbonization

FLD Technologies is a pioneer in profitable, viable, regionally implementable, and networkable integrated hydrogen solutions. We provide solutions and products for green fuel, power, heating, and cooling. FLD Technologies’ patented technology adds new dimensions to the circular economy. Naturally available raw materials become energy without environmentally harmful CO2 emissions. In addition, we remove greenhouse gases from the atmosphere, clean the air, and return carbon to the earth as natural, solid material. We enable ecosystems that have the potential to create a negative CO2 footprint.

HyRegio® : Orchestrated platform with networkable regional hubs for self-sufficient hydrogen production from biogas.

The value of HyRegio®: air purification and returns from the CO2 avoidance price

According to the current state of the art, biogas plants are used exclusively to generate electricity.

The orchestrated platform HyRegio® from FLD Technologies adds a new dimension to the previous, conventional methods. Compact, regionally deployable, and highly efficient modules allow the production of hydrogen, heat, and electricity/cooling from biogas, or bio feedstock. The advantage for producers, investors, and consumers is that the modules turn regions into self-sufficient energy suppliers.

Our plants clean the atmosphere of CO2 previously emitted by industry. The raw materials processed in the biogas plant have so far removed CO2 from the atmosphere. We use this material – unlike in the past – not to burn it to produce new CO2. Instead, the biogas is converted into hydrogen, electricity, heat and cooling in the methane splitter by plasma pyrolysis. The remaining carbon from bio feedstock is geologically stored as a harmless solid. In our process, no gas is injected into the earth, but is removed from the atmosphere as biocarbon. We call our process mGHGm® because we significantly reduce GHG (“Minimizing Green House Gas Measurably”). With this method we materialize the so far unused ecological potentials of conventional CCS.

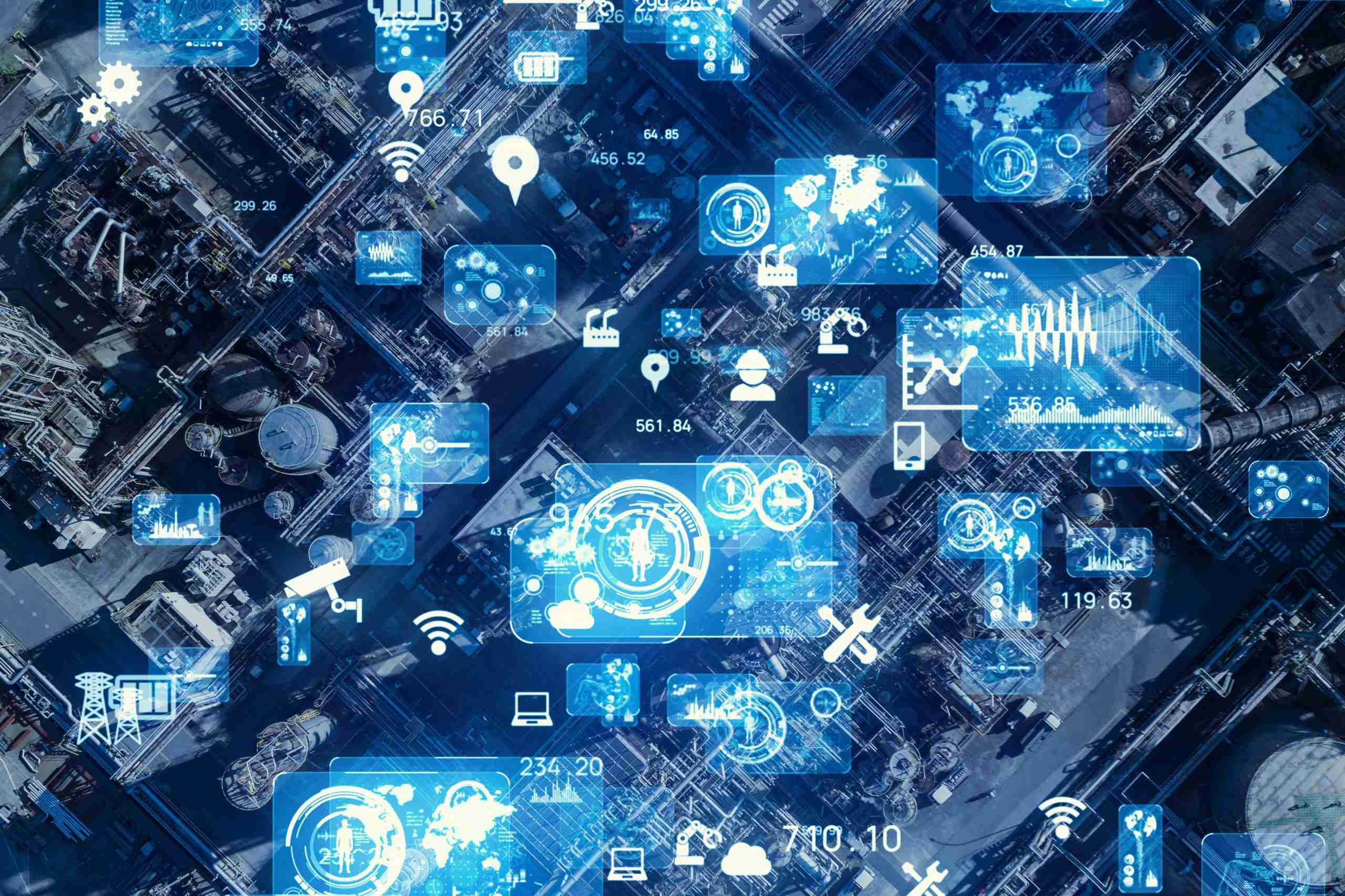

HyRegio® hubs as data provider and crystallization seed of an innovative hydrogen ecosystem with strong growth prospects

The affordable and profitable HyRegio® hubs can network with each other and beyond on a cloud-based technology platform. The data obtained serves as a decision-making basis, for example, for energy producers, utilities, the automotive and other industries, transportation companies and associations, providers of smart mobility solutions, municipalities, politics, initiatives, etc.

HyRegio®-Hub: The advantages

More efficient biogas processing

The classic separation processes for obtaining bio-methane are investment- and energy-intensive. Residual gas must be subjected to costly aftertreatment. The FLDT process is pressureless. It no longer requires compression of the gas for separation. It yields methane gas with a concentration of over 99 vol.%. Learn more …

Energy-saving bio-methane splitting

The FLDT process of plasma pyrolysis for methane cracking requires only a quarter of the electrical energy that would be needed to produce the same amount of H2 in electrolysis. Deionized water is no longer required. In this way, the process proceeds entirely without greenhouse gas emissions. Learn more …

Air decarbonization with mGHGm®

In contrast to conventional CCS processes, with our mGHGm® method we store solid biocarbon geologically and permanently in the ground. No gas is injected into cavities under pressure. By returning carbon to the earth in a beneficial way, we achieve a negative carbon footprint.. Learn more …

Combined heat and power plant (CHP)

Combined heat and power plants (CHP) convert chemical energy of biogas into green electricity and heat. Methane releases are avoided, which are 23 times more harmful than CO2 emissions. The HyRegio® hub gives CHPs a new role: by operating biogas plants economically and with reduced emissions.. Learn more …

Hub- and cloud-based data mining

The decentralized and networked HyRegio® hubs from FLD Technologies acquire valuable data on consumption, demand, and peak times. These are stored in a cloud for evaluation and exchange between hubs. Data not previously collected provides a basis for further optimization. Learn more …

Hydrogen distribution system

HyRegio® provides for the demand-oriented supply of communities with electricity, heating/cooling and hydrogen. To meet these requirements in a flexible, stable and profitable way, the H2 production is extended by a local distribution system. Previously unrecorded information provides an important, unique basis. Learn more …

Unique selling propositions

Green H2 from biogas everywhere

Measurable purification on the atmosphere

Negative CO2 footprint possible

Self-sufficiency through H2 electricity

Gain in efficiency and profitability

FLDT products

Green hydrogen

In the future, hydrogen will be the main energy carrier alongside electricity. It does not occur in pure form in nature and must be produced technically. It is a non-toxic, colorless and odorless gas.. Learn more …

Heating and cooling

In the HyRegio® process, a basic distinction can be made between two modes of operation, which can be used alternatively: ecological electricity production and sustainable hydrogen production. Learn more …

Green electricity

With HyRegio®, electricity is only one of the possible products. The decision on the mode of operation – electricity or hydrogen – lies with the producer. This creates the opportunity to economically optimize the plant as a whole. Learn more

Green CO2

The CO2 produced in biogas upgrading can be called “green CO2” or bio-CO2. It can be used as a product for e.g. greenhouses or as a raw material in the chemical industry. Learn more …

Certificate of Origin

The splitting of biogas into hydrogen and pure carbon with its immobilization causes the minimization of greenhouse gases. The proof by certificates is a value-adding product. Learn more …

Not collected data

HyRegio® offers a distribution platform for regional hubs. There, distribution channels can be marketed centrally. Data mining offers many application possibilities. Learn more …

Investment opportunities

1. Significant additional revenue from CO2 emission trading through application of the mGHGm® process

The extraction of CO2 from the air by means of mGHGm® represents an exclusive opportunity to use biogas plants for value creation – far more effectively than before.

2. Scaling effects through modular design of the plants

Significant scaling effects are easy to achieve because the plants are modular. This optimizes investment costs. The modules can be duplicated in accordance with the “Economy of Series”.

3. Considerable market potential due to new economic perspectives for biogas plants

The number of biogas plants in Germany is around 10,000, and the market is expected to grow further through greater inclusion of anaerobic post-digestion of biowaste and purification of wastewater.

4. Flexibility in the product portfolio

The process offers the possibility of switching between “green electricity” and “green hydrogen” in a value-optimizing manner. With “green H2”, other co-products such as bio-CO2 or bio-carbon are also available. Both operating modes have in common that a substantial heat supply is available.

The distribution system of HyRegio® facilitates the access to “green” hydrogen, which contributes to increased acceptance of the product, e.g. H2 mobility.

5. Digitization of the regional energy supply

Coupling single HyRegio® hubs to digital platform offers the opportunity not only to develop the hubs into an economic “ecosystem”, but also to actively support the co-operation of municipalities in energy supply.

6. Synergy effects through practical sector coupling "on site"

The product diversity of HyRegio® enables sector coupling at the municipal level. Flexible adaptation to local conditions coupled with current data leads to economically attractive results.

The management team

Dr. Marek Fulde

- Process engineer, 30 years of experience in leading positions in research and international plant engineering and construction.

- Several years of experience in environmental technology and flexibilization of energy-intensive processes

- Consultant in the European Commission project ‘CertifHy Guarantees of Origin (GO) for Green Hydrogen’.

Benjamin Richters

- Process engineer, 30-year process engineer and project manager with several years of experience in international plant construction

- Experience in building and leading international project teams in petrochemical plant construction

- Developer of processes for the chemical recycling of waste materials’.

Partners

Patents

FLD Technologies has intellectual property rights.

Methane gas with a concentration of 99% by volume

To provide the bio-methane required for the downstream splitting process, part of the biogas is processed in the first unit of the plant. Classic separation methods used in the production of bio-methane for feeding into the public natural gas grid, such as physical adsorption, chemical absorption with organic solvents, membrane, and cryogenic processes, are investment- and energy-intensive. The remaining residual gas, still containing traces of methane, requires complex and cost-intensive treatment (post-combustion). The process used by FLDT is pressureless – that is, no compression of the gas is required for separation. It yields methane gas with a concentration of over 99% by volume.

Climate-neutral residual gas, no after-treatment/combustion necessary

The residual gas produced in addition to biomethane is climate-neutral (“green CO2”) and can be released into the atmosphere without further treatment. If applicable, it can be used together with the residual heat available in the process to intensify production in greenhouses. Post-treatment, such as post-combustion to remove the climate-damaging methane from the residual gas, is not required.

Highly energy-efficient plasma pyrolysis with green electricity and zero greenhouse gas emissions

In this stage, the biomethane gas obtained is splitted into solid biocarbon and hydrogen. Plasma pyrolysis is used here. In an innovative reactor, biomethane is exposed to microwaves and forms gas plasma. In the absence of oxygen, biomethane is heated and breaks down into its components, carbon and hydrogen. Electricity from renewable energy sources, primary biogas, is used to generate microwaves. The specially developed reactor design by FLDT enables the optimal reaction conditions through adapted fluid dynamics. The plasma process requires only a quarter of the electrical energy that would be needed to produce the same amount of H2 in electrolysis. Deionized water – a basic condition in electrolysis – is also not required. The process works without greenhouse gas emissions.

Returning CO2 as solid bio-carbon

Unlike conventional CCS (Carbon (Dioxide) Capture and Storage) processes, our air decarbonisation with mGHGm® method immobilizes solid biocarbon geologically and permanently. No gas is pressed into cavities. By beneficially returning carbon to the earth, we achieve a negative carbon footprint.

No pressure injection of carbon dioxide into the ground

In the classic CCS process, exhaust gases from the combustion of coal or natural gas are captured and injected under pressure underground. CO2 is supposed to combine with rock and be permanently immobilized. This process is considered unsafe because the permanent bonding of CO2 to minerals is controversial in the scientific community, and new releases into the atmosphere can be expected. Furthermore, the injection of CO2 under high pressure could lead to earthquakes. The mixing and dissolving of carbon dioxide with groundwater could also cause so-called “cold geysers”, again leading to emissions.

Another aspect of making CCS technology more difficult to use is a lack of infrastructure that would be required to transport CO2. This is due to the fact that emission sources such as power plants or cement plants are located far from suitable CO2 storage sites. This would require the construction of pipelines.

In contrast, the production of biogas represents a natural process for capturing anthropogenic CO2 from the atmosphere. mGHGmS® process consistently carries this process through to completion. We pyrolyze biogas, capture solid carbon and immobilize it permanently. In this process, one ton of solid carbon corresponds to the storage of approx. 3.6 t of CO2.

Converting chemical energy into electricity and heat

The CHP is an integral part of every biogas plant. As part of the promotion of renewable energy, it is used to convert the chemical energy of biogas into electricity and heat. It avoids methane releases, which are 23 times more harmful than CO2 emissions. HyRegio®-Hub gives CHP a new role: an economical and emission-reduced operation of biogas plants.

Cleaning the atmosphere from harmful CO2

The expansion of the bio plant with biomethane splitting enables a transformation of the sole production of electricity into the additional use of the plant for hydrogen production. Another benefit is the cleaning of the atmosphere from harmful CO2. Depending on the current electricity price, the HyRegio® hub can be switched to supply electricity to the public grid or hydrogen production.

This procedure differs significantly from the so-called flexible operation of a biogas plant.

In flexible operation, a biogas plant is only allowed to feed electricity into the grid for a few hours a day under electricity price control. Compared to the first support phase, high operating costs due to wear of the gas engines and increased maintenance requirements are to be expected in addition to a loss of revenue.

HyRegio-Hub®, on the other hand, is capable of producing not only electricity but also other products such as hydrogen and ensuring the continuous operation of the CHP units. This allows an advantageous extension of the product range (hydrogen, CO2 avoidance (GoO), “green CO2”, bio-carbon).

Hydrogen distribution system

The concept of HyRegio® is to supply communities with electricity, heating/cooling, and hydrogen. To fulfill this requirement, the H2 production is extended by a local distribution system.

Increasing economic efficiency

The demand for hydrogen is continuously recorded by allowing customers to place orders electronically in a cloud-based platform. Based on this, the production and distribution of hydrogen are planned in line with electricity production. In the process, the electricity/hydrogen ratio is balanced in a value-generating manner. The hydrogen is then distributed in the surrounding area using specially developed trailers.

To increase efficiency, the cloud platform is used by multiple hubs. This enables the optimization of the overall network.

Decentralized and connected HyRegio® hubs

The decentralized and networked HyRegio® hubs from FLD Technologies acquire data on consumption, demand, peak times, and consumption patterns in the respective locations. These are stored in a cloud for algorithm-based evaluation and exchange between the hubs.

Optimization of processes, products, services

The information, which has not yet been collected, provides energy producers, utilities, associations, municipalities, etc. with a sound data-based foundation. It is used for network expansion, predictive maintenance as well as the optimization of their processes, products, and services.

Furthermore, reliable demand and production data enable the use of modern AI-supported planning methods for supply processes.

The analysis (data mining) of the data collected in the cloud can be used for regional development as well as for commercial purposes.

Green hydrogen

In the future, hydrogen will be the main energy carrier alongside electricity. It does not occur in pure form in nature and must be produced technically. It is a non-toxic, colorless, and odorless gas.

Hydrogen burns CO2-free. It is used, among industrial applications, to generate electricity in fuel cells, which are used to power cars and trucks. H2 can also be used for heating or cooling. However, mobility is the main application of hydrogen.

The analysis (data mining) of the data collected in the cloud can be used for regional development as well as for commercial purposes.

Heating/Cooling

In the HyRegio® process, a distinction can be made between two modes of operation that are used alternatively: electricity production and hydrogen production. Both modes of operation have in common that heat is produced as an additional product. The thermal energy generated in the splitting process is particularly valuable. Because of its high temperature, it can be used not only for heating but also for higher-value applications. Cooling by means of absorption chillers is also economically and commercially viable at this temperature level.

Green electricity

Electricity generation is the “classic” application of biogas. Under the current legal framework conditions, remaining with the sole application of electricity requires considerable investments in plant flexibilization. Despite subsidies, the profitability of the investment focused on one product still depends on market effects.

When applying the HyRegio® concept, electricity is only one of the possible products. It can still be offered. The decision on the plant’s mode of operation – electricity or hydrogen – lies with the producer and not exclusively with the grid operator. This creates the opportunity to economically optimize the plant as a whole.

Bio CO2

The CO2 obtained in biogas processing can be called “green CO2” or bio-CO2 due to its biogenic origin. It can be used as a product or raw material for e.g. the chemical industry.

Certificate of Origin

The splitting of biogas into hydrogen and pure carbon with its immobilization can be described as “materialized” capture and storage of carbon dioxide. This causes a purification effect, i.e. minimization of greenhouse gases in the atmosphere (mGHm®). Depending on the raw materials used for biogas production, a varying negative CO2 avoidance effect can be achieved. Proof of this is provided in the form of certificates of origin (Guarantee of Origin – GoO). The CO2 avoidance documented there represents a value-added product.

Data not previously collected

HyRegio® offers a distribution platform for regional production hubs. There, distribution channels for all products (H2, Bio-CO2, Bio-C, GoO, electricity, heat/cold) can be centrally managed and marketed. A B2B relationship between the hubs (e.g. coproducer agreement) can also be mapped and realized there. The evaluation of the collected data (data mining) offers a broad basis for regional or commercial application possibilities.

Green hydrogen from biogas

By definition, hydrogen is green if it uses feedstock and energy from renewable sources in its production. The HyRegio®-H2 is produced exclusively from biogenic methane. Both raw material (methane) and electric power are derived from renewable feedstock – biogas.

Purification effect on the atmosphere

By using biogas as feedstock and applying mGHGm® processes, a unique cleaning effect is achieved – CO2 is removed from the atmosphere. The CO2 binding (photosynthesis) taking place in the plants, as well as the subsequent anaerobic fermentation of the biomass to biomethane, are extended by the splitting of the methane. This allows the carbon dioxide emitted into the air to be converted into solid carbon. The mGHGm® process is designed to immobilize solid, “materialized” carbon – a 3.5-fold CO2 equivalent – i.e. by geologically and permanently storing it. In this way, fossil carbon that was burned during anthropogenic use is returned to the earth’s soil.

Negative CO2 footprint possible

Biogas is greenhouse gas neutral, i.e. the amounts of CO2 taken from the air in photosynthesis are released again when biogas is burned. This effect is absent in mGHGm® because solid carbon from biogas is immobilized and no longer burned. The CO2 captured by plants is permanently bound in the form of carbon and cannot escape into the atmosphere. The CO2 footprint becomes negative and the air purification effect is achieved.

Self-sufficiency bio-H2 electricity & heat

HyRegio® concept offers communities the opportunity to realize regional supply with renewable electricity and heat and green hydrogen. Thereby biogas as input material allows extensive self-sufficiency because all 3 products are produced exclusively by using biogas. Thanks to the air-purifying effect municipalities deliver their contribution for the avoidance of global warming. Statistically, a biogas plant of 250 kW can supply 350 households.

High efficiency and profitability

The HyRegio® concept is characterized by high efficiency. This is first of all due to the continuous production of biogas. The feedstock for further production steps is always available and is not dependent on the weather or seasonal conditions as is the case with wind power or photovoltaics. Secondly, the concept is characterized by product diversity, which allows value-enhancing planning and control of production. Finally, the production plants can be operated in a network, which allows further optimization of the manufacturing and logistics processes.